Environmental Protection

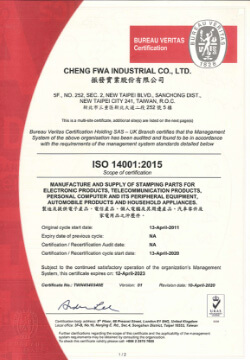

Environmental Commitment and Management System

In recent years, emphasis has put on the control of pollution emissions. Different reduction of pollutions and management systems has been the focus of the implementation of pollution control among the enterprises. The company was certified by ISO 14001 in 2011 and has continued to enhance the overall environment which is helpful for the increase of business operations. Meanwhile, it also fortifies the export competitiveness and enhances the company's image. We promise to continue maintaining the ISO 14001 environmental management system as to prevent any possible pollutants and fulfill our social responsibility.

Given the rise of environmental awareness, Cheng Fwa Industrial Co. Ltd. has been committed to the work of environmental protection for several years. It is hoped that through environmental management together with spontaneous and continuous improvement, we could improve the environmental conditions, reduce the actual impacts to the environment, and protect the Earth's limited green resources and environment.

Apart from the organizational structure, we have also established an interdepartmental Environmental Management Committee who is responsible to the integration of the upper level of the organization and the advance of interdepartmental activities. Also, a management representative is selected as to supervise, coordinate, implement, enhance and provide all resources needed for the environmental management system (including human resources, specialized skills, technology, finance, etc.)

Green Products

As to achieve the goal of sustainable operation, the company has requested the supply chain to introduce green product management which can effectively control the usage of the limited substances. Thus, Cheng Fwa Industrial Co. Ltd has promoted the green product management system and was certified with ISO-QC080000 Hazardous Substance Process Management (HSPM). It will certainly maintain theeffectiveness of the system.

Based on IECQ QC 080000, Hazardous Substances Free (HSF) control shall be requested in the quality control system. Not only shall it comply with the RoHS, it shall also comply with the customers’ requests. In the same year, it was also certified with PUreGMS(GA) HSF certification by Pegatron Corporation.

-

HSF Policy

In the pursuit of green product productions, hazardous substances shall be prevented while regulations shall be complied. We shall also protect the Earth and reduce the impact to the ecosystem. Thus, Cheng Fwa has established the HSF Policy of 「regulation compliance, green manufacturing process and customer satisfaction」 .

-

Restricted Substance Management

The materials used for the products are all free of hazardous substances and free of substances that would damage the environment. Cheng Fwa produces metal stamping products. From the transportation of the raw materials (metal plate) into the plants, the production of the products till the packaging, delivery and transportation, no impacts would be caused over the environment and the health and safety of the personnel.

-

Usage of Raw Materials

From the transportation of the raw materials into the plants, the production of the products till the packaging, delivery and transportation, all materials are designed to use the minimum amount of materials as to decrease the usage of materials in each of the product.

-

Green Supply Chain

Integrity and honesty have always been the conditions for choosing Cheng Fwa’s partner supplier as we consider them as our long-term partners. We believe that only with similar corporate culture, the partnership would be longer.

2017 Since 2021, based on EICC and our company’s 「 Subcontractors Management Program」 , our suppliers have started to sign the 「Supplier Environmental Commitment」and 「Supplier Social Responsibility Commitment」 . The top 10 suppliers shall have their auto evaluation and a second party inspection. The results are shown in the following table:

| Year | Amount of Agreement | Agreement Rate | EICC Auto Evaluation | EICC Second Party Inspection |

|---|---|---|---|---|

| 2018 | 118 | 70% | Avg. score 90 | Avg. score 78 |

| 2019 | 122 | 71% | Avg. score 90 | Avg. score 78 |

| 2020 | 125 | 71% | Avg. score 90 | Avg. score 78 |

| 2021 | 127 | 72% | Avg. score 90 | Avg. score 78 |

| 2022 | 131 | 72% | Avg. score 90 | Avg. score 78 |

Our major production plants are in Taiwan. More than 90% of the suppliers also have their plants in Taiwan. The flood in Thailand in 2011 and the tsunami and nuclear disaster in Japan did not affect the supply of the raw materials. In response to the trend of green consumption, the company has prioritized products, instruments, equipment and other indirect materials with green labels or eco-friendly labels in order to reduce environmental pollution. Not only do we request the compliance of regulations in the transportation management of the raw materials by the suppliers, the impact of the trucks and containers are also taken into consideration. Thus, guards are arranged to control the traffic and to ensure the transportation safety as to prevent any anomaly or accident. Based on our statistics, there was no accident in 2021 and in the past few years with the trucks and the containers

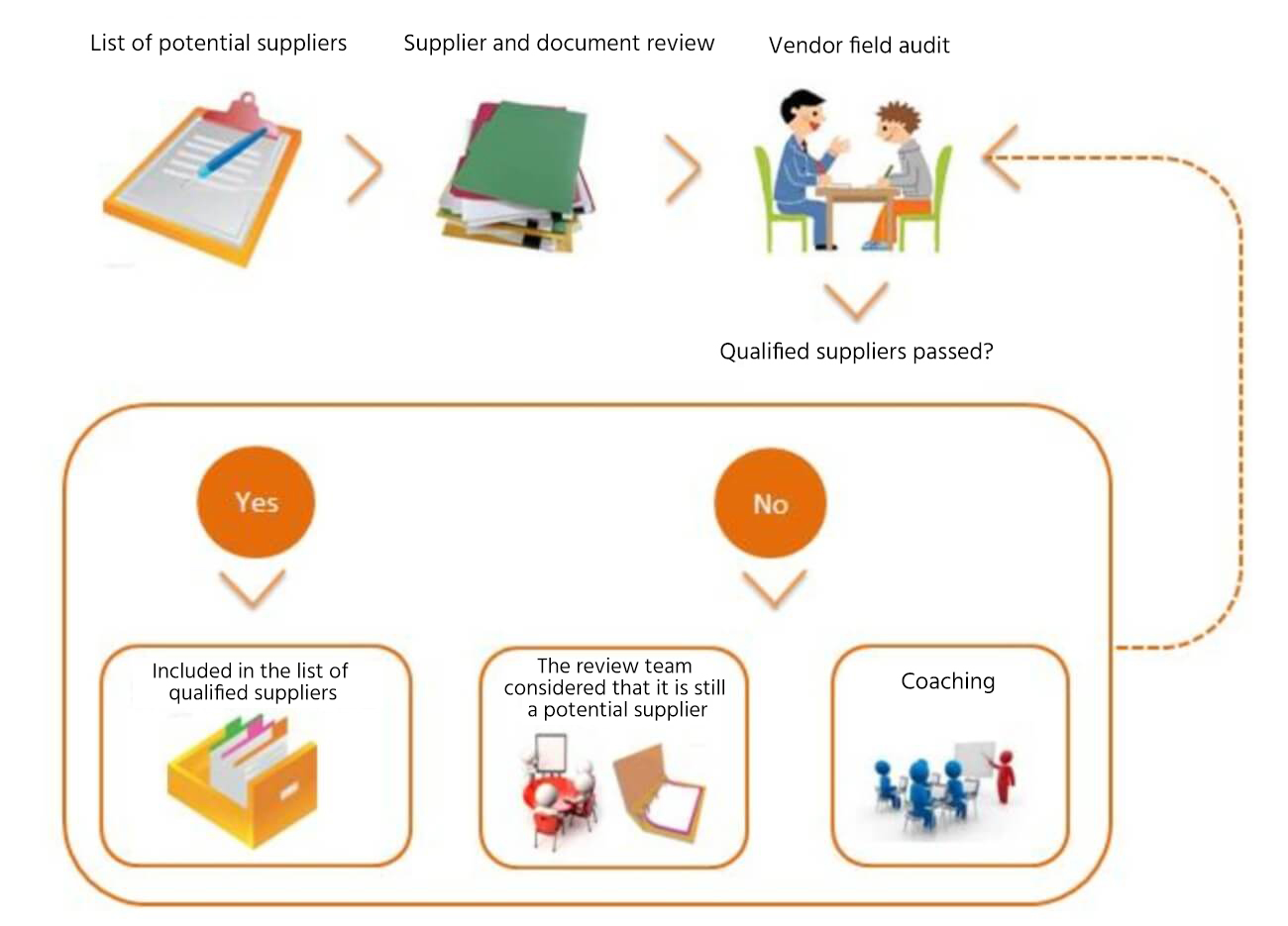

In terms of the manufacturing and production of green products, we have control of sources and evaluation and assistance to the suppliers. The flow chart is shown in the following diagram. The hazardous substances are strictly controlled during the production process. In order to prevent the entry of hazardous substances into the parts and the materials during the production process, analysis of hazardous substances (with XRF) and monitoring are done during the importation of the materials. We also assist the suppliers to obtain certification of green products. In order to meet green product standards, we also request the suppliers to comply with international standards or other related green product specifications

Carbon Reduction

- We actively promote energy saving measures at the offices and the production areas.

- During 2010 – 2011, all lights are replaced by electrode less lamps or T5 lamps at the production area and at the offices. This could save 40% of the light power.

- The exit indicators have been replaced with LED exit indicators once the old ones were malfunctioning.

- All personal computers and office machines are set up in energy-saving mode. Power shall be turned off when they were not used.

- All air conditioning temperature shall be increase to 26 – 27 oC as to save power (for every increment of 1 oC, 6% of the power can be saved).

- In December 2017, the replacement of high-efficiency air compressors with 100 horses and two units (with government incentives) is estimated to save about 5% of the total electricity in 2018.

| Year | Direct Energy | % | Indirect Energy | % |

|---|---|---|---|---|

| 2018 | 151.89 Tons/Year | 7.79% | 1798.05 Tons/Year | 92.21% |

| 2019 | 157.11 Tons/Year | 8.78% | 1632.68 Tons/Year | 91.22% |

| 2020 | 172.57 Tons/Year | 8.61% | 1831.1 Tons/Year | 91.39% |

| 2021 | 182.99 Tons/Year | 7.98% | 2111.4 Tons/Year | 92.02% |

| 2022 | 230.21 Tons/Year | 10.70% | 1921.59 Tons/Year | 89.30% |

(Power: 0.612 Mt / Thousand Degrees; Gasoline: 2.2631 Mt / Kiloliter; Diesel: 2.6060Mt / Kiloliter CO2)

- There is low water consumption as washing is not needed during the manufacturing process.

- Faucets are replaces with self-closing faucets. Promotion of water saving concept.

- The usage of algae inhibitors in the cooling tower as to prolong the frequency of water changing. Water is changed every three months.

| Type | 2018 | 2019 | 2020 | 2021 | 2022 |

|---|---|---|---|---|---|

| Water Consumption (Thousand Degree) | 33.7 | 26.7 | 26.2 | 38.1 | 58.7 |

Environmental Pollution Management

With the purpose of energy saving, eco-friendly and green production, carbon reduction is being implemented as to increase energy usage rate and to decrease pollution and energy consumption.

The internal air pollution mainly comes from the VOC volatile gases in the oil washing and network printing process. Yet nitrogen oxides and sulfur oxides are not produced.

Every half a year, an inspection company would come to collect the wastewater and report to EPA. The EPA evaluations of irregular wastewater collection samples are all in the regulatory standard.

- General Industrial Waste

- Waste, packaging materials and other non-recycling value wastes.

- Wastewater Treatment Sludge

- Inorganic sludge. (treated by the sludge removal processing industry)

- Recyclable Resources

- Iron, aluminum, copper, cardboard boxes, plastic bottles, beverage cans, lamps.

In terms of chemicals management, we would first carry out the classification and risk assessment of the hazardous substances within the chemicals. Accident prevention operating measures are established in concern of the chemicals. The description is as the following:

All chemicals, including ink, plate cleaners, degreasing agents shall be inspected before entering into the plants. After the inspection, the person in charge shall place them at a fixed visible place and label the substance safety chart for colleagues’ reference. If the chemicals is used up, the empty bottle shall be placed in a ventilated area and place it at the recycling zone so that the suppliers would take in charge of it.

Safety and health training and education as well as first aid measures are taught to the chemicals personnel. Protection equipment shall be wore and the chemicals shall be used as indicated by the SOP. If the chemicals remains, it shall be placed at the indicated area with a tray as to prevent chemical leakage. The main operators and the supervisors shall receive training from the outside as well as organic solvent safety and health educational training with certificate.

Promotion of Green Concept

- Seminars: EPA was invited to promote the concept of 「 green life」

- To encourage the staff to become carbon reduction white collars, such as taking the public transportation

- Every Tuesday is the Vegan Meal Day in the staff restaurant.

- To encourage the staff to follow a simplistic life‐style. Do not waste resources.

- To promote energy-saving activities in the office and the plants.

- One-hour light off during the nap.

- Sponsorship for environmental associations; promotion of green activities.

International Ministries

Beach cleanup activity

Environmental protection activities

For more information, please read Cheng Fwa 2022 Corporate Responsibility Report